Thermoforming and Plastic Manufacturing: Revolutionizing the Food Industry

Thermoforming, a versatile manufacturing process that involves heating a plastic sheet to a pliable state and forming it into a desired shape using...

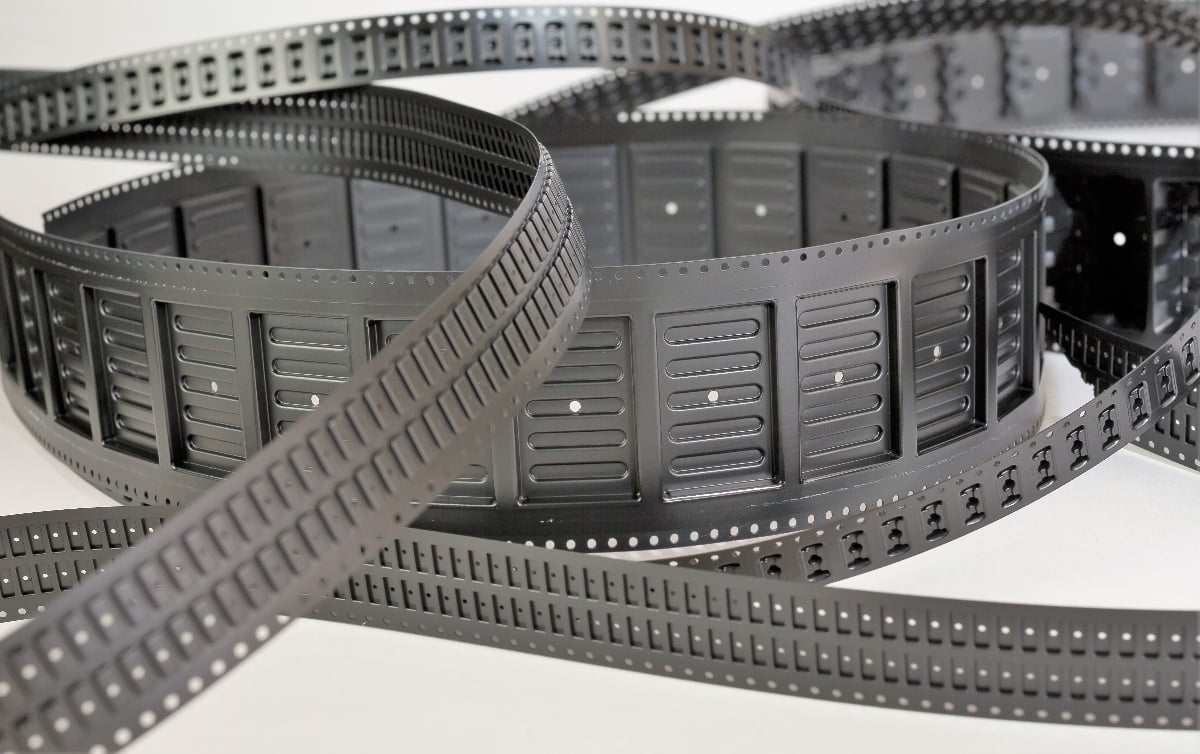

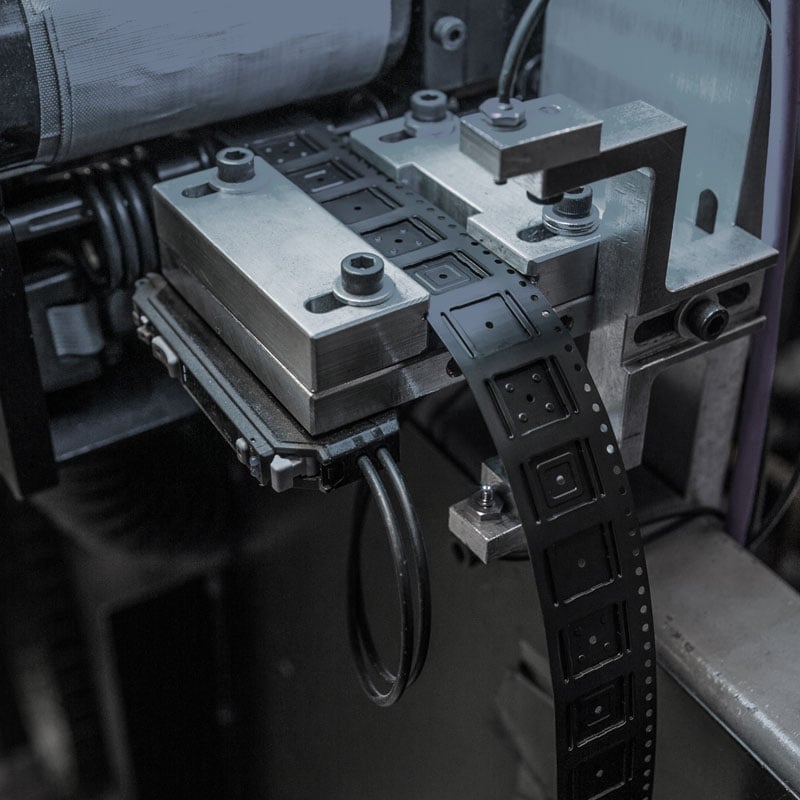

At Tek Pak, we pride ourselves on being a leader in our industry, pushing the envelope of innovative ideas, processes, and products. Our reinvestment of time and financial resources in our tech, equipment, and people keeps us on the cutting edge. In the mid-1980s, Tek Pak owner Tony Beyer realized how computerized chips and robotic mechanized machinery were escalating the worldwide electronics industry's speed to market. In a garage, he built the first tape and reel machine to help revolutionize the rate at which circuit boards could be loaded with chips and placed into infinite electronic products.

To this day, Tony Beyer still holds many of the original tape and reel machinery patents used in the machinery built here at Tek Pak. Getting in on the ground floor and being recognized as a founding father of the evolution of carrier tape, Beyer's revolutionary thinking and inventions rank as some of his proudest accomplishments.

Carrier tape soon became a natural part of the Electronic Components Industry Association (ECIA). As carrier tape became a staple in the automation world, it became apparent that national and international standards were required. In order to standardize, a special committee was formed called the Automated Components Handling Group.

Since its inception, the ACHG has been chaired by someone from Tek Pak. The original chair, Tek Pak head of RnD, Scott Carter, handed the reigns over to Tek Pak head of Quality Control, Brian Mathany, in 2016. The group's purpose is to monitor the standards written regarding methods of the electronic handling components in automated processes (mainly carrier tape and trays). The group meets every six months to review any industry questions and communications. Guidance is provided to companies that might not have a complete understanding of how to handle electronic components in accordance with these standards. The ACHG is also in direct communication with their European and Asian counterparts that control similar versions of these standards to try and align them with one another. The ACHG is also tasked with examining any new automation technology for handling electronic components that may benefit from standardization.

While all of the committee work requires additional time and effort, the benefit to Tek Pak is considerable, acting as an ally, getting involved, and helping shape industry standards year after year. As a member of the ACHG, Tek Pak has the opportunity to learn about and get out in front of many industry and product trends that may be emerging regarding automated component handling. At the same time, the ACHG also acts as a watchdog, helping to resolve issues and rectify situations concerning electronics packaging constraints placed upon component and machine manufacturers.

Tek Pak is proud to be a member of the ACHG and a leader, helping to set national and international standards in the automated electronics industry.

Thermoforming, a versatile manufacturing process that involves heating a plastic sheet to a pliable state and forming it into a desired shape using...

Earlier this month, our own Vice President of Innovation & Sustainability, Dr. Scott Carter, was featured in the 2024 fourth quarter edition of the...

The manufacturing industry has transformed significantly over the last decade, driven by technological advancements and evolving consumer demands....