Healthcare

Quality Assurance

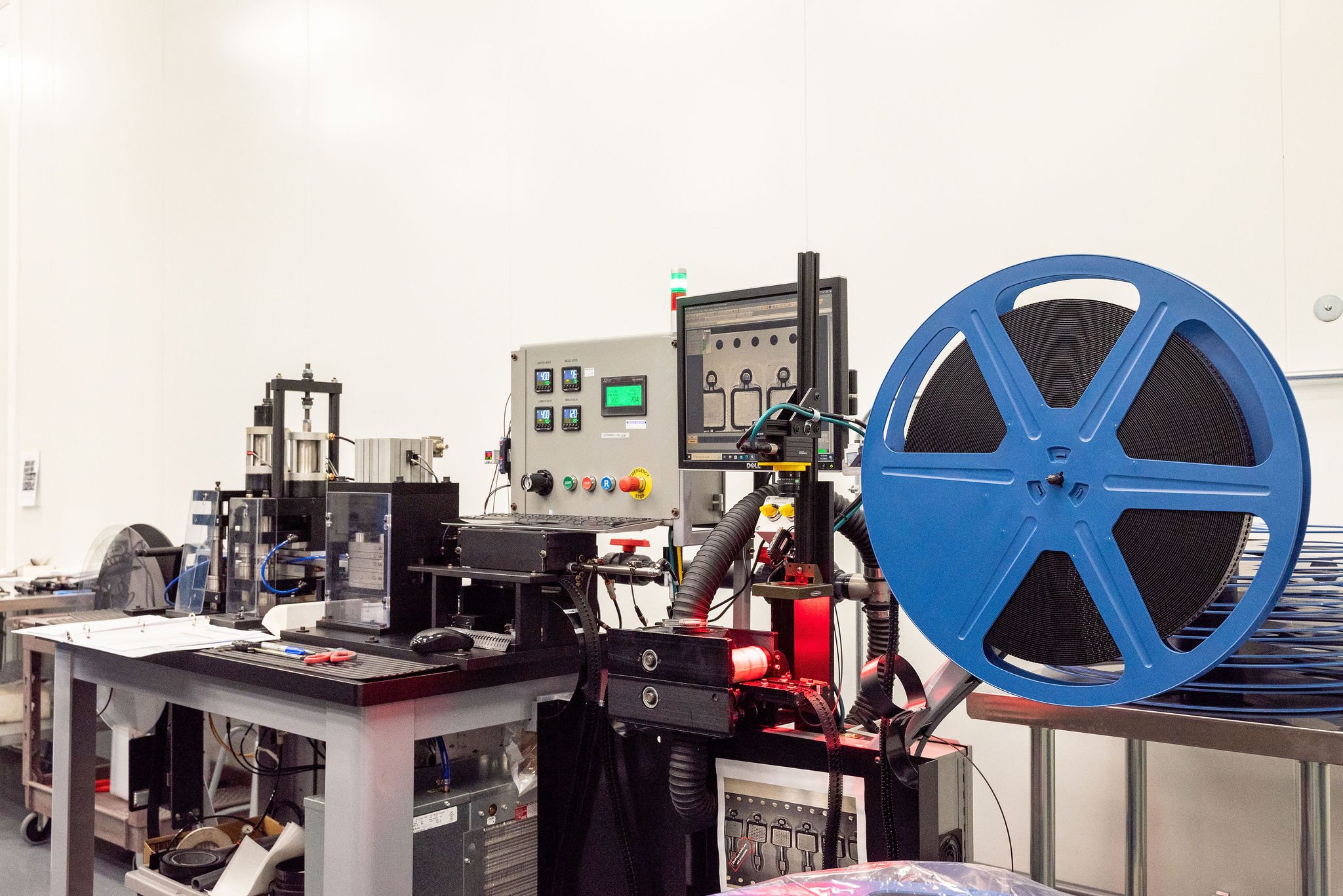

Tek Pak offers cleanroom manufacturing services for leading players in the health sector. Our standard material forming uses materials such as PETG and polystyrene while our non-standard specialty materials include multi-layer, thin gauge, and barrier films. We are ISO 13485 certified for the manufacture and laser trimming of thermoformed products for the medical device industry and our packing solutions range from soft-touch products used in wearable technology to drug delivery innovations. Our quality management system provides full-lot traceability from raw materials to finished products.

Turnkey Solutions

Tek Pak offers turnkey solutions for all your Healthcare thermoforming needs. Our rigorous inspection process ensures that measurements are taken at key milestones which guarantees a quality product that exceeds our customer’s expectations.

Healthcare Thermoforming FAQs

-

Most Common Thermoformed Medial Packages/Products?

Tek Pak’s Class 8 clean room is often used by our health care products customer to produce thermoformed trays. These trays while low cost, offer excellent protection for delicate medical devices for their movements thru their original production process to the packaging and transportation to the medical provider or patient.

Thermoformed trays are one of the most common packages in healthcare. Other, top winners in this category are forming films, laminations, bags and pouches. -

How Can Thermoforming Solutions Improve The Medical Industry?

With the pandemic came an increased scrutiny of the safety and security of medical products including many where a sterile package is required. Thin thermoforming packaging is one of the best solutions available today. These packages are easy to design and change and can also be mass produced in sterile production facilities such as the Class 8 Clean room at Tek Pak.

Certified

Certified ISO 9001 and ISO 13485 design, development and manufacturing.Material Forming

Standard material forming includes the following items: PETG, Polystyrene, Polypropylene, and Polyethylene.Non-Standard Materials

Non-standard materials such as multi-layer materials, thin gauge, and barrier films.

Traceability

Traceability from raw material to finished product.

Thorough Inspections

Product inspection is done at key manufacturing milestones (startup, in-process and final piece).

Want to Talk?

Our knowledgeable staff is available to answer your technical questions, provide quotes, and coordinate your designs with our engineering staff. Please call us at: (630) 406-0560, or if you like please fill out the form on this page.