Laser Trimming Services

Ideal for All Applications

Our lasers are ideal for trimming, cutting, and etching parts with intricate designs that would be too expensive or difficult for mechanical punch tooling, especially for products under development. In many cases, we laser trim prototype parts because it reduces the time and cost involved with trim tooling. We are able to trim and etch formed parts if the contours are not too drastic, so please describe your trimming challenge to us!

Expert Trimming, Techniques, and Materials

-

Materials: Most Thermoplastics

A wide variety of materials can be laser cut/converted:

- Thermoplastics

- Thermoset plastics

- PET

- PS

- HDPE

- LDPE

- PP

- Ultem™

- PEEK™

- PA

- Rubber

- RTC Silicone

- Pressure Sensitive Adhesives

- Foam

- Paper

- Felt

- Leather

- Cork

- Fiber

-

Dimensional Limits

- Part size maximum: 10” x 10”

- Part thickness maximum: ~0.040” (please inquire)

-

Multiple Techniques in the Same Production Pass

- Through cut

- Kiss cut

- Scoring

- Ablation

- Perforating

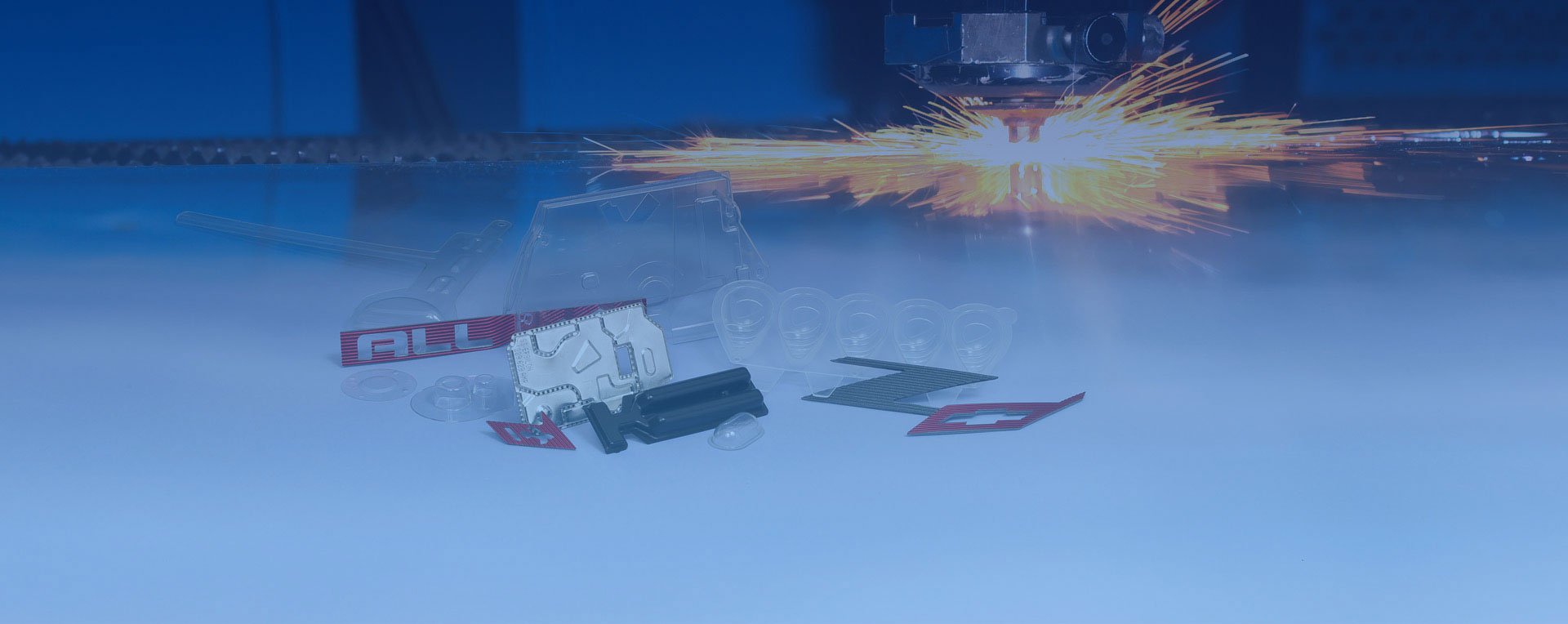

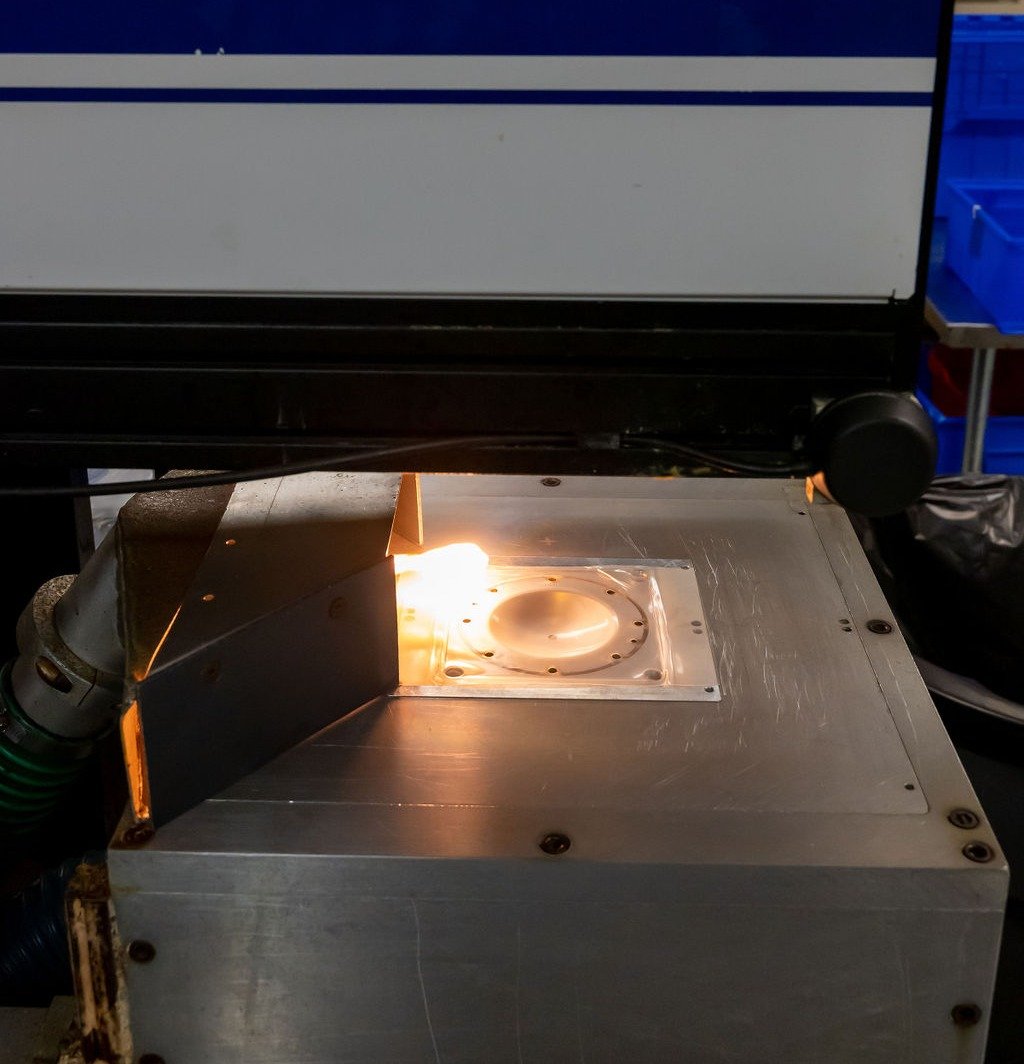

Our Laser Trimming in Action

Laser Trimming Advantages

Eliminates Expensive Cost of Tooling

Design Changes Rapidly Implemented

Intricate Cutting Patterns

Non-Contact

Our process precisely ablates coatings on multi-layer materials without damage to underlying materials.

Fast and Flexible

We have the best solutions for cutting, trimming, and converting your materials and subassemblies into finished parts. We offer quick-turn service, and we use your design or we develop for you. We are perfect for product development and prototyping.

Examples of Parts

We utilize a wide range of parts including plastic thermoforms, gaskets, seals, washers, flexible packaging, stencils, and graphic arts.

Want to Talk?

Our knowledgeable staff is available to answer your technical questions, provide quotes, and coordinate your designs with our engineering staff. Please call us at: (630) 406-0560, or if you like please fill out the form on this page.