Thermoforming and Plastic Manufacturing: Revolutionizing the Food Industry

Thermoforming, a versatile manufacturing process that involves heating a plastic sheet to a pliable state and forming it into a desired shape using...

The world of electronics relies on countless tiny components, from resistors to integrated circuits, that work together to power our devices. But have you ever thought about how these delicate parts get from the factory to a finished product?

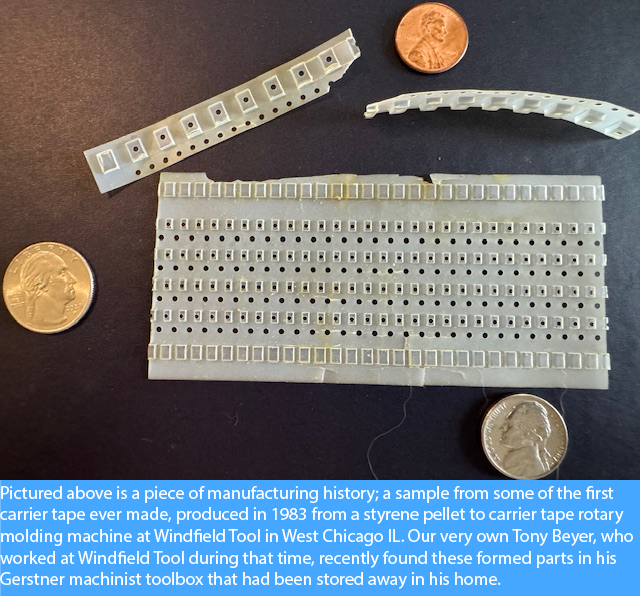

That's where Carrier Tape comes in. By collaborating with some local visionaries, a couple of drag racers who worked together at a company called Windfield in West Chicago, Illinois, saw a need for automation in the electronics assembly process. This seemingly simple strip of plastic plays a critical role in ensuring the safe and efficient transport, storage, and assembly of these miniature marvels.

Imagine a long, continuous belt made of plastic, typically polystyrene or polycarbonate that looks like a movie film reel. Now, picture individual pockets or cavities punched into this belt, each perfectly designed to hold a specific electronic component. Finally, both edges are lined with drive holes to advance the film accurately. That's the essence of Carrier Tape.

One of the biggest reasons why all electronics are relatively inexpensive to build is due to the electronics industry adopting Carrier Tape standards 40 years ago. This change helped standardize automation systems and improve efficiency. But what else makes it so important?

While Carrier Tape is extremely beneficial to the electronics industry, it can also be used to improve other industries, like the medical or pharmaceutical sectors. Since we are focusing more on the electronics industry, here is a closer look at some more Carrier Tape applications:

As the electronics industry continues to miniaturize components, the role of Carrier Tape becomes even more crucial. With ongoing advancements in materials and design, Carrier Tape will keep pace, ensuring the safe and efficient flow of these vital components for years to come.

So, the next time you use your smartphone or any other electronic device, take a moment to appreciate the tiny heroes behind the scenes – the Carrier Tape that helped bring it to life.

Our commitment to our clients is to provide them with high-quality and innovative thermoforming solutions, and we would love to discuss your packaging needs. To get started, you can visit our contact page, give us a call, or request a quote.

Thermoforming, a versatile manufacturing process that involves heating a plastic sheet to a pliable state and forming it into a desired shape using...

Earlier this month, our own Vice President of Innovation & Sustainability, Dr. Scott Carter, was featured in the 2024 fourth quarter edition of the...

The manufacturing industry has transformed significantly over the last decade, driven by technological advancements and evolving consumer demands....