Thermoforming and Plastic Manufacturing: Revolutionizing the Food Industry

Thermoforming, a versatile manufacturing process that involves heating a plastic sheet to a pliable state and forming it into a desired shape using...

3 min read

Tony Beyer

:

Dec 11, 2023 3:06:43 PM

Tony Beyer

:

Dec 11, 2023 3:06:43 PM

Thermoforming is a plastic product manufacturing technique where a plastic sheet is melted onto a mold to create the shape. The extruded thermoplastic typically comes on rolls or sheets and is fed into the thermoforming machine for conversion into packaging. The roll’s size and the plastic sheet’s thickness will vary depending on the application. The cost of the plastic increases with thickness, so manufacturers strive to use the thinnest starting gauge that will produce the results they need.

There are two types of thermoforming: thin gauge and heavy gauge. Thin gauge thermoforming, used for manufacturing disposable or recyclable containers, lids, blister packs, and packaging, uses rolls of plastic less than 1.5mm (0.060”) thick. Heavy gauge thermoforming uses sheets of plastics that range from 1.5mm – 9.5mm (0.060 “– 0.375”) and is used for non-disposable applications like equipment covers, enclosures, and car interior parts. In this article, we will be focusing on thin gauge thermoforming.

The roll of plastic is fed into the machine and heated until it becomes pliable. Once it is soft and flexible, it conforms to the mold using a vacuum or pressure. It is allowed to cool so that it solidifies into the desired shape. The excess plastic is then trimmed to create the precisely made thermoformed product.

It is important to note that because it starts with a flat sheet, some features may not be possible to mold or may add additional costs. Additionally, the molded features impact both the inside and outside of the packaging. So, a formed rib will have a male impression on one side and a corresponding female impression on the other side. As the material conforms to the mold, the stretching reduces the wall thickness. Proper design and tooling become important.

1. Design – The design process starts with material selection because each plastic reacts differently and has different properties. Choose a material that aligns with the product’s purpose, for example, clarity, rigidity, or static resistance. Once the material is selected, the part itself can be designed. Proper part design will be critical for efficiency and manufacturing. Some critical design characteristics include draft angles, radii and corners, wall thickness, undercuts, draw ratio, and tolerances. Working with experts in thermoforming product design early in the process will ensure you have the desired outcome.

2. Prototyping – Once your design is established, prototyping is a helpful step to ensure the form, fit, and function are correct prior to production. Prototypes use single cavity molds. It may take several iterations. The protective packaging on your microwave dinner, nonconductive trays cradling an electronic component, and packaging safeguarding medical devices all depend on the thermoforming process to create packaging shaped to secure and protect the product. The versatility and cost-effectiveness make this plastic molding process popular across industries. of a prototype before you are ready to scale up to production.

3. Production tooling – There are two primary types of thermoforming tooling. A positive tool is convex-shaped (male tooling) and a negative tool is concave-shaped (female tooling). With positive tooling, after heating the plastic sheet, it is placed in the tool, and a vacuum or air pressure draws it into the mold to create the shape. The tool dimensions become the outside dimensions of the plastic component. When a negative tool is used, heated plastic is draped over it and clamped into place. The plastic is drawn to the mold by vacuum or air pressure and takes shape. With this mold, the tool dimension becomes the inside dimension of the part. Each method has pros and cons and should be chosen according to the specific application. Depending on the need, tooling can have various coatings and features, such as water-cooled cavities, moving plug assist, and air-actuated clamps and strippers.

4. Production – Brands often start with smaller quantities and try them in test markets or clinical trials, for example. These can be made in multi-cavity molds quite efficiently. Very large corporations will usually move the thermoforming in-house once it reaches large volumes (billions of pieces a day).

Material selection will depend on the needs of the product. It is critical to balance the benefits of the material with its less advantageous characteristics. Every project should start with a comprehensive review of the options and the project goals to determine the best material.

Some common thermoform materials include:

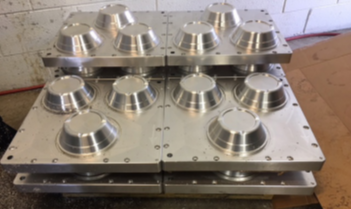

At Tek Pak, we take on challenging applications that others will not, taking you effortlessly from design through production tooling. Our R+D department works on developing solutions using unique and challenging materials as well as solutions for laser trimming, cutting, and etching parts. With one of North America’s largest thermoform tool rooms, we have experience creating molds for various machine platforms with fast lead times. All of our molds are made from aluminum, so your prototype parts are production quality. To assist with the challenge of launching a new product, we offer prototyping and low-volume thermoforming as well, and we offer class 8 clean room manufacturing for medical and food applications.

Our commitment to our clients is to provide them with high-quality and innovative thermoforming solutions, and we would love to discuss your packaging needs. To get started, you can visit our contact page, give us a call, or request a quote.

Thermoforming, a versatile manufacturing process that involves heating a plastic sheet to a pliable state and forming it into a desired shape using...

Earlier this month, our own Vice President of Innovation & Sustainability, Dr. Scott Carter, was featured in the 2024 fourth quarter edition of the...

The manufacturing industry has transformed significantly over the last decade, driven by technological advancements and evolving consumer demands....